HOME > NEWS & EVENTS > Details

Carbon Steel with High Temperature Powder Painting Support Cage

Shandong Aobo High Temperature Powder Painting (HTPC) is a modern method of pre-coating steel elements for corrosion protection. The advantage of this processing is its high aesthetics and good ground for further covering methods such as powder coating. Support cages pre-coated have many years guarantee at working temperatures of up to 300℃

Working temperature range: ~ 240 ℃, Peak temperature: 240 ~280℃, Maximum temperature is up to 300 ℃ (no recommend)

Manufacturing Process:

1. Welding the cages, cleaning the surface of the cages

2. Put the cage into the shot blasting machine line, to remove the burr;

3. Put the cage into painting room, and Huajia®, Alesta® Powder painting treatment, the thickness of painting is about 60μm~120μm

4. Put the cage into a big oven, firstly temperature is 220℃, about 120 min, after that, temperature is 200℃, about 30 min, then natural cooling.

5. Put the final cages into package crates

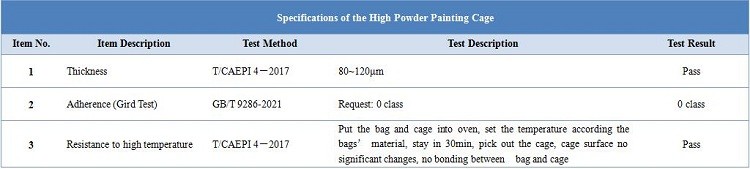

Specifications of the High Powder Painting Cage ((HTPC)

1. Example of thickness test which gives a result of cage thickness (115μm, 95μm, 96μm) >80μm

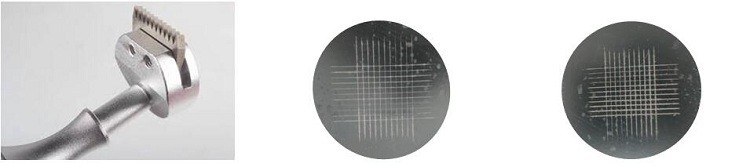

2. Grid test

This method specifies a procedure to determine the adhesion of the paint to the support, of the paints to detachment from the supports when a pattern is created on the surface, up to the support. The test consists in making an incision on the coating with an appropriate cutter or metal blade, reaching the substrate. Create horizontal and vertical incisions to shape the reticle on the test surface. Apply adhesive tape to cover the incision area and remove vigorously. Visually observe the grid area to determine the result.

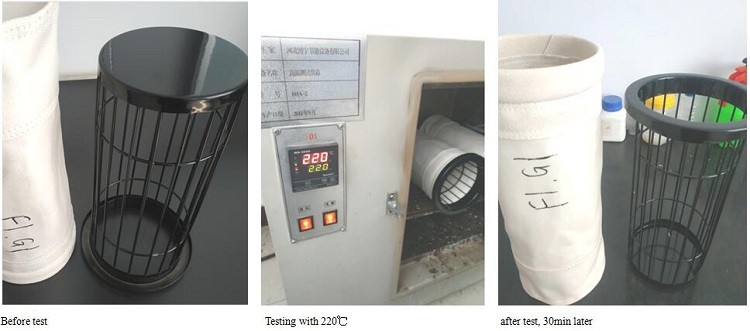

3. Resistance to high temperature

Example: Glass-woven Filter bag + HTPC cage test, 30 min later, cage surface no significant changes, no bonding between bag and cage

For more information, please kindly reach us